- GST NO. : 24AMRPK5853A1Z2

heightentechnology@gmail.com

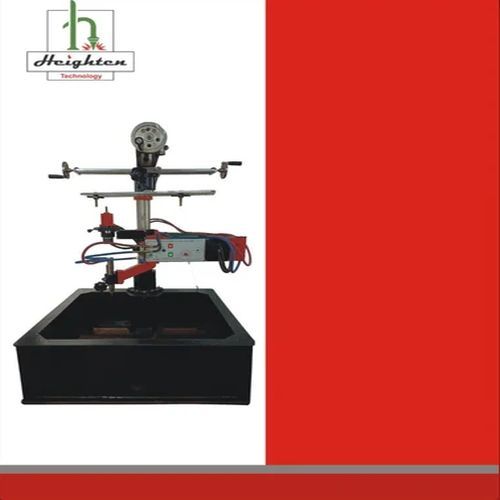

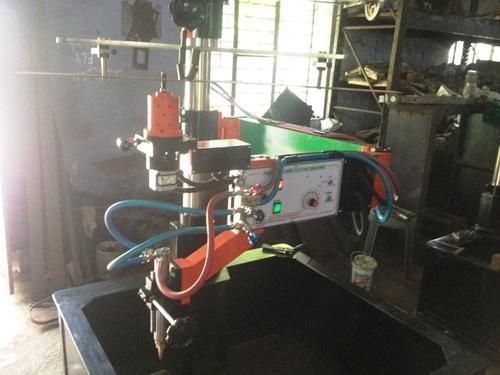

Industrial Gas Cutting Machine

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Heavy Duty Profile Gas Cutting Machine, HT 2000 Profile Gas Cutting Machine, Mild Steel Profile Gas Cutting Machine, Pillar Mounted Heavy Duty Profile Gas Cutting Machine, Profile Cutting Machine, Profile Gas Cutting Machine and Semi Automatic Profile Gas Cutting Machine from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | HT |

| Automatic Grade | Automatic |

| Driven Type | Electric |

| Fuel Gas Type | LPG |

| Torch Type | Gas Torch |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Metal |

| Color | Blue |

| Packaging | Cardboard Box |

| Application | Industrial Metal Cutting |

| Power Source | Gas |

| Cutting Capacity | Depends On The Gas And Nozzle Used |

| Weight | Approximately 20-30 Kg |

| Dimension | Standard Industrial Size |

| Brand Name | HT |

| Model | 2000 |

| Warranty | 1 Year Limited Warranty |

| Country of Origin | Varies |

| Price | Varies Based On Supplier |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Condition | New |

| Country of Origin | India |

| Material | Mild Steel |

| Color | Depends On Manufacturer, Typically Yellow Or Red |

| Packaging | Standard Packaging For Machinery |

| Application | Industrial Metal Cutting |

| Power Source | Gas (acetylene, Propane, Or Natural Gas) |

| Cutting Thickness | Depends On Model, Typically Up To 300 Mm |

| Cutting Speed | Varies Based On Model, Typically 100-1000 Mm/min |

| Features | Includes Cutting Torch, Gas Regulators, Hoses, And Cutting Tips |

| Model | Specific Model Not Provided |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Mounting | Pillar Mounted |

| Duty | Heavy Duty |

| Material | Metal |

| Color | Depends On Manufacturer |

| Packaging | Standard Packaging |

| Application | Industrial Cutting Applications |

| Power Source | Gas |

| Cutting Method | Gas Cutting |

| Cutting Thickness | Depends On Model |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Stainless Steel |

| Voltage | 220V |

| Finishing | Polished |

| Machine Weight | 100-200kg |

| Automatic Grade | Semi Automatic |

| Packaging Type | Carton Box |

| Power Source | Electric |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Warranty | 1 Year |

| Brand Name | HT |

| Fuel Gas Type | LPG |

| Torch Type | Gas Torch |

| Material | Mild Steel |

| Grade | Semi-automatic |

- HT 1300 is a Professional, Tough and Durable Profile Cutting Machine

- This non tiring machine has to be foundation mounted and can be used in multiple shifts for large Production Application

- A Magnetic Racing Roller which moves around a Tin Sheet Template makes the cutting Torch cut the exact shape with perfect accuracy

- HT 1300 can cut Mild Steel and Low Alloy Carbon Steel with Oxy Fuel

- The Machine can cut from 5 mm to 200 mm Plate thickness with Oxy Fuel

- The Machine can cut any complex shapes like Flanges, Stars, Hooks, Ellipse, Triangles or even Circles, Squares, Rectangles and even Straight Lines

- The Machine can cut any shape from 20 mm dia to 1300 mm square

- The Machine runs on just single phase 230 V power and consumes very less electricity

- It is supplied with Permanent Magnet Tracing Head

- The Machine is very popular in Indian Fabrication Industry and is used by small workshops to Large Ship Fabricators

- Cutting Capacity: Any shape up to 1300 mm dia

- Max. Straight Cut: 1500 mm in length

- Cutting Speed: 60 mm/min to 3000 mm/min

- Power Supply: 220/250 Volts AC. 50 Hz

- Motor: 1/20 HP. AC/DC. Series FHP

- Speed Control: Variable by Disc Knob

- Maximum Current: 1 Amps

- Fuse: Bottle Type 1 Amp

- Tracer Movement: Clockwise/Stop/Anticlockwise

- Torch: Injector Type

- Torch Holder: Rack and Pinion (Vertical)

- Hose Connection: 3/8’’G (Fuel Gas LH and Oxygen RH)

- Gross Weight: 400 kgs (Approx)

Benefits

- It is an all Aluminium Hinge, Right handed machine Ease of operation

- Its Repeatability accuracy is plus minus 1 mm

- It is supplied with permanent magnet hence no magnet failure

- It is a 95% Mechanical machine: Negligible Maintenance, Seldom Breaks down

- Large Speed Range: from 70 mm/min to 3000 mm/min

- It has tracing roller up and down lever: Enables flange cutting in single setting

- It has X and Y axis (Dual) slide mechanism: enables quick job setting, faster production

Additional Spares:

- Small Fixed Spanner: 1 Nos

- Adjustable Spanner: 1 Nos

- Nozzles:2 Nos

- Nozzle Cleaner: 1 Nos

- LN Key: 2 Nos

- Template Holder: 2 Nos

- Tracer Roller: 6 Nos

- Output Current (Ampere):

0-100 - HT 1300 is a Professional, Tough and Durable Profile Cutting Machine

- This non tiring machine has to be foundation mounted and can be used in multiple shifts for large Production Application

- A Magnetic Racing Roller which moves around a Tin Sheet Template makes the cutting Torch cut the exact shape with perfect accuracy

- HT 1300 can cut Mild Steel and Low Alloy Carbon Steel with Oxy Fuel

- The Machine can cut from 5 mm to 200 mm Plate thickness with Oxy Fuel

- The Machine can cut any complex shapes like Flanges, Stars, Hooks, Ellipse, Triangles or even Circles, Squares, Rectangles and even Straight Lines

- The Machine can cut any shape from 20 mm dia to 1300 mm square

- The Machine runs on just single phase 230 V power and consumes very less electricity

- It is supplied with Permanent Magnet Tracing Head

- The Machine is very popular in Indian Fabrication Industry and is used by small workshops to Large Ship Fabricators

Specifications:

- Cutting Capacity: Any shape up to 1300 mm dia

- Max. Straight Cut: 1500 mm in length

- Cutting Speed: 60 mm/min to 3000 mm/min

- Power Supply: 220/250 Volts AC. 50 Hz

- Motor: 1/20 HP. AC/DC. Series FHP

- Speed Control: Variable by Disc Knob

- Maximum Current: 1 Amps

- Fuse: Bottle Type 1 Amp

- Tracer Movement: Clockwise/Stop/Anticlockwise

- Torch: Injector Type

- Torch Holder: Rack and Pinion (Vertical)

- Hose Connection: 3/8’’G (Fuel Gas LH and Oxygen RH)

- Gross Weight: 400 kgs (Approx)

Benefits:

- It is an all Aluminium Hinge, Right handed machine Ease of operation

- Its Repeatability accuracy is plus minus 1 mm

- It is supplied with permanent magnet hence no magnet failure

- It is a 95% Mechanical machine: Negligible Maintenance, Seldom Breaks down

- Large Speed Range: from 70 mm/min to 3000 mm/min

- It has tracing roller up and down lever: Enables flange cutting in single setting

- It has X and Y axis (Dual) slide mechanism: enables quick job setting, faster production

Additional Spares:

- Small Fixed Spanner: 1 Nos

- Adjustable Spanner: 1 Nos

- Nozzles:2 Nos

- Nozzle Cleaner: 1 Nos

- LN Key: 2 Nos

- Template Holder: 2 Nos

- Tracer Roller: 6 Nos

- Output Current (Ampere):

0-100

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | HT |

| Material | Mild Steel |

| Application | Industrial |

| Cutting Speed | 0-200 mm/min |

| Max Cutting Thickness | >80 mm |

| Max Cutting Width | 1000-2000 mm |

- HT 1300 is a Professional, Tough and Durable Profile Cutting Machine

- This non tiring machine has to be foundation mounted and can be used in multiple shifts for large Production Application

- A Magnetic Racing Roller which moves around a Tin Sheet Template makes the cutting Torch cut the exact shape with perfect accuracy

- HT 1300 can cut Mild Steel and Low Alloy Carbon Steel with Oxy Fuel

- The Machine can cut from 5 mm to 200 mm Plate thickness with Oxy Fuel

- The Machine can cut any complex shapes like Flanges, Stars, Hooks, Ellipse, Triangles or even Circles, Squares, Rectangles and even Straight Lines

- The Machine can cut any shape from 20 mm dia to 1300 mm square

- The Machine runs on just single phase 230 V power and consumes very less electricity

- It is supplied with Permanent Magnet Tracing Head

- The Machine is very popular in Indian Fabrication Industry and is used by small workshops to Large Ship Fabricators

- Cutting Capacity: Any shape up to 1300 mm dia

- Max. Straight Cut: 1500 mm in length

- Cutting Speed: 60 mm/min to 3000 mm/min

- Power Supply: 220/250 Volts AC. 50 Hz

- Motor: 1/20 HP. AC/DC. Series FHP

- Speed Control: Variable by Disc Knob

- Maximum Current: 1 Amp

- Fuse: Bottle Type 1 Amp

- Tracer Movement: Clockwise/Stop/Anticlockwise

- Torch: Injector Type

- Torch Holder: Rack and Pinion (Vertical)

- Hose Connection: 3/8’’G (Fuel Gas LH and Oxygen RH)

- Gross Weight: 400 kgs (Approx)

Benefits

- It is an all Aluminium Hinge, Right handed machine Ease of operation

- Its Repeatability accuracy is plus minus 1 mm

- It is supplied with permanent magnet hence no magnet failure

- It is a 95% Mechanical machine: Negligible Maintenance, Seldom Breaks down

- Large Speed Range: from 70 mm/min to 3000 mm/min

- It has tracing roller up and down lever: Enables flange cutting in single setting

- It has X and Y axis (Dual) slide mechanism: enables quick job setting, faster production

Additional Spares:

- Small Fixed Spanner: 1 Nos

- Adjustable Spanner: 1 Nos

- Nozzles:2 Nos

- Nozzle Cleaner: 1 Nos

- LN Key: 2 Nos

- Template Holder: 2 Nos

- Tracer Roller: 6 Nos